The PP Compounds Plant is located in an individual industrial building, next to the Plant of PP Resins in Ensenada, Buenos Aires, in order to take full advantage of services, maintenance, logistics and storage.

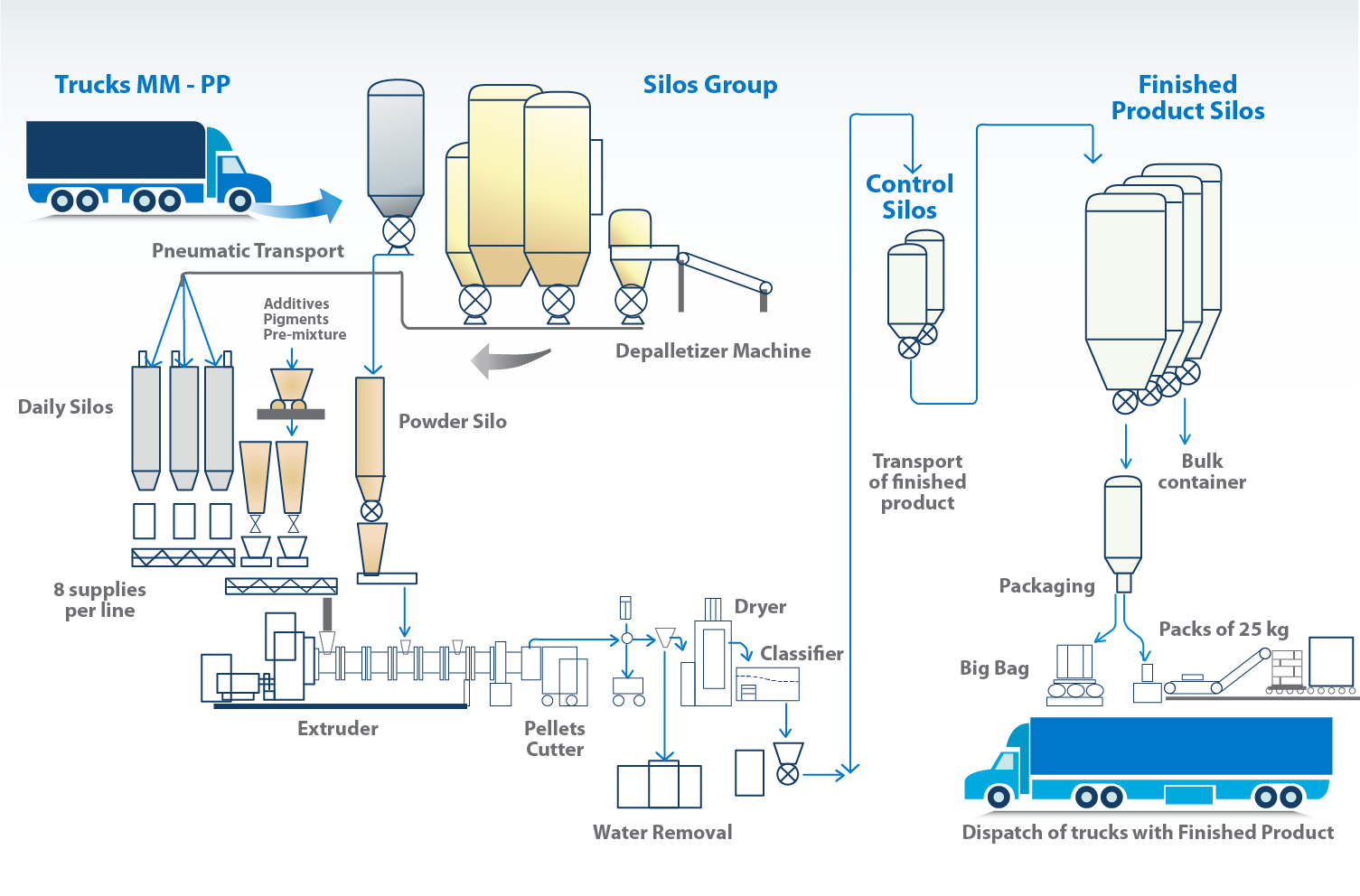

In the image we can see three stages.

Production Process

It has 4 industrial extruders, two of them are JSW Japan Steel Works and two are W&P Werner und Pfleiderer. It also has an extruder of reduced size for small productions and development of new products.

It has in place a complete laboratory, including color analysis. In addition, it has cooperation agreements with the laboratories of its technology supplier.

Stage 1:

Raw materials are received in different forms and types of packaging, which will be used in the production process of PP compounds.

For their incorporation to the process, they have to be dumped into intermediate silos from where they will be distributed by automatic equipments.

Stage 2:

That automatic equipments ensure the continuous and steady inflow of each material through the loss of weight.

Once the different components of a compound are added, they must be mixed uniformly. For that purpose, an extruder is incorporated to the process.

The extruder has a cylinder at around 200°C which has a pair of screws inside designed for high capacity of mixing.

The co-rotating screw system allows a thoroughly mix of the polymer mass with components (powder, carbonates or fiberglass), additives and pigments.

Then, it takes place the palletizing and cooling of the melted material coming out of the end of the extruder through a perforated plate.

Stage 3:

At this stage, the finished product pellets are store in intermediate silos for their analysis and classification.

They are later packed in big bags of 700 or 1000 kg.

The PP compound is now in the proper conditions to be delivered to the clients.